Inhaltsverzeichnis

Features

Precision locknuts

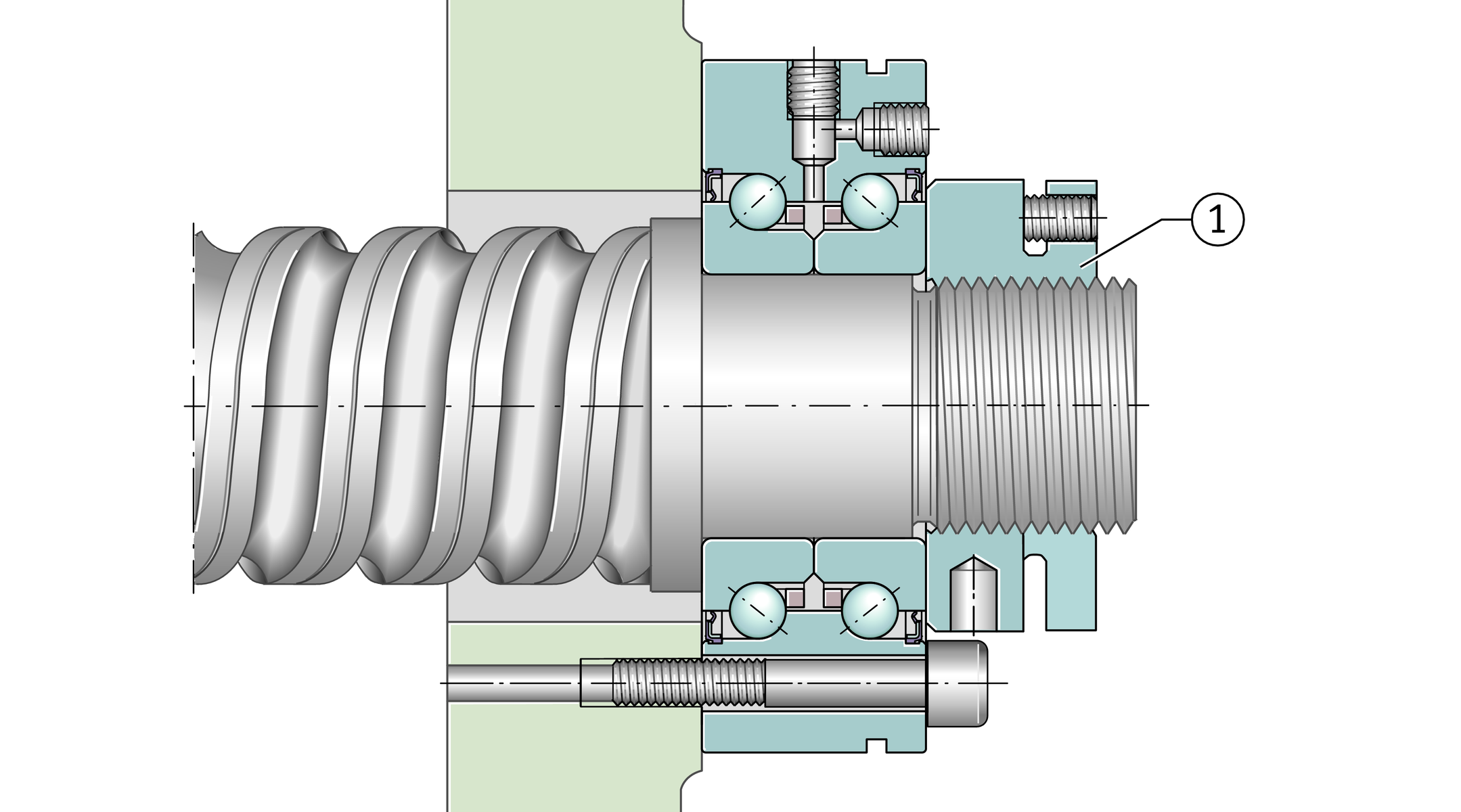

Precision locknuts are used where high axial forces must be supported and high axial runout accuracy and rigidity are required, ➤ Figure and ➤ Figure.

The thread and the axial face of the locknut in contact with the rolling bearing are produced in a single clamping operation. This allows very high axial runout accuracy to be achieved.

The available precision locknuts AM, ZM and ZMA can be used several times if handled correctly.

Axial locking by segments

Precision locknuts AM with axial locking are divided into several segments for applying the locking forces. When the hexagonal socket grub screws are tightened, the segments are elastically deformed. As a result, the thread flanks of the segments are pressed against the flanks of the shaft thread and give a high frictional force that acts to prevent loosening of the nut. The axial runout of the nut is not affected by this method of locking.

Mounting clearance with locknut AM for axial locking

Locking by radial locking pegs

Precision locknuts ZM and ZMA are secured against rotation by means of two radially acting locking pegs, ➤ Figure. ZMA is the heavy series.

The locking pegs are manufactured together with the internal thread of the locknut. They mesh like comb teeth in the thread of the shaft without affecting the axial runout or damaging the thread.

The locking pegs are secured by grub screws with a hexagonal socket arranged concentrically over the locking pegs.

Mounting clearance with locknut ZM, ZMA for radial locking

Design and safety guidelines

Shaft threads for the precision locknuts must be precision machined, see table .

Recommended shaft thread

Shaft thread to DIN 13-21 to DIN 13-24 Tolerance class | |

|---|---|

Medium | Fine |

6g | 4h |

ACHTUNG

The journal thread must support the locknut over its whole width.

Breakaway torque

The breakaway torques ML given in the dimension tables are based on a locknut tightened against a rigid shaft shoulder to the reference tightening torque MAL and secured.

Ultimate axial load

The axial ultimate loads FaB are valid for a journal thread of tolerance class 6g or better and a minimum strength of 700 N/mm2.

For dynamic loading, the permissible value can be taken as 75% of the ultimate load FaB.

Mounting guidelines

The characteristics of the bearings are only valid when used in combination with INA precision locknuts and the associated tightening torques given in the dimension tables.

ACHTUNG

Locknuts must be fully screwed onto the shaft thread.

Bearings and precision locknuts should only be mounted and dismounted in accordance with the Mounting and Maintenance Manual TPI 100.

Further information

TPI 100, Bearings for Screw Drives, Mounting and Maintenance Manual

Download and ordering: http://medien.schaeffler.de..

Precision locknuts for axial locking

Precision locknuts AM for axial locking can be tightened using a hook wrench of type B to DIN 1810 that engages in four, six or eight holes around the circumference, ➤ Figure.

The grub screws are then tightened in a crosswise sequence to the specified tightening torque MA using an Allen key. Dismounting is carried out by uniformly loosening the grub screws of all segments in order to prevent a single segment being left tensioned.

ACHTUNG

Tightening by means of just one segment is not permissible. For tightening, a socket AMS can be used that ensures uniform loading of all segments. The socket AMS must be ordered separately.

For tightening using the socket AMS, a hook wrench of type B or type A to DIN 1810 or an FAG socket can be used, see link.

If precision locknuts AM are fitted using the socket AMS, a maximum of twice the tightening torque of the bearing according to the dimension table is permissible.

Segments can be axially deformed if the grub screws are not tightened uniformly in a crosswise sequence or the locknut AM is not fully screwed onto the shaft thread. The specified tightening torque MA in the dimension table must be observed.

Mounting tools for precision locknuts AM

Precision locknuts for radial locking

For tightening of locknuts ZM and ZMA, a hook wrench to DIN 1810A that engages in one of the four slots around the circumference or an FAG socket can be used, ➤ Figure.

The two grub screws are then tightened alternately to the specified tightening torque MA using an Allen key; for MA, see dimension tables for the bearings.

For dismounting, the two grub screws are first loosened and the locking pegs loosened by light impacts with a plastic hammer on the outside surface of the locknut (in the vicinity of the screw holes).

The locknut can then be easily unscrewed without damaging the journal thread.

Mounting tools for precision locknuts ZM

FAG sockets

For simple tightening and loosening of precision locknuts ZM on shafts, the sockets LOCKNUT-SOCKET-KM, ➤ Figure are suitable. In combination with the socket AMS, this socket is also suitable for precision locknuts AM. They require less space on the circumference of the locknut than hook wrenches and allow the use of torque wrenches.

For increased reliability, FAG sockets should be secured using a locking pin and rubber ring. They therefore have a hole for the locking pin and a groove for the rubber ring. The locking pin and rubber ring are included in the scope of delivery.

FAG socket for precision locknuts ZM and sockets AMS

Accuracy

Accuracy of precision locknuts: see table .

Axial runout

Axial runout of axial face to thread** | Metric thread in accordance Tolerance class |

|---|---|

μm | Fine |

5 | 5H |

**The axial face and thread are machined in a single clamping operation, in order to achieve very high accuracy. Before measurement, the precision locknut is clamped against a rigid shoulder on a threaded mandrel to a defined tightening torque. The grub screws remain loosened.